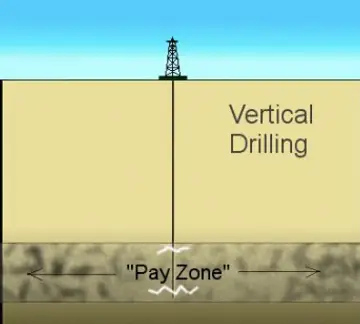

Vertical/Conventional Drilling

Vertical, or conventional drilling has been used since the 1800’s to extract gas from reservoirs deep within the earth.

Quite simply, it is just that – a well that is drilled straight down (or vertical) into the earth. Sometimes it is difficult or impossible to set up drilling operations above a natural gas reservoir, for instance, under an urban area in which surface conditions would not be conducive or legally allowed.

Because of these vertical limitations they have the possibility of being resolved through horizontal drilling.

Horizontal/Unconventional Drilling

Horizontal, or unconventional drilling is based off of directional drilling technology where the lower part of the wellbore parallels the oil zone. With this type of directional drilling, oil and gas wells can be drilled at various angles underground.

Horizontal wells have become a preferred method of recovering oil and gas from reservoirs that occupy horizontal strata (or nearly so) because they offer greater contact with the surface area than vertical, or conventional wells. With the ability to steer and maneuver the well in different directions, operators can hit hard to reach areas and stimulate the reservoirs very effectively.

Directional drilling combined with high-pressured injections of organic and inorganic materials into low-permeable shale formations to extract the gas or oil contained therein is the process known as “fracking”. With these injections, the shale rock is cracked to allow the release and flow of the trapped oil and gas from tiny pore spaces back up through the wellbore to the surface.

However, drilling for unconventional natural gas requires a whole set of new environmental issues since it requires more chemicals, more water and more wastewater injection wells.

While the cost factor for a horizontal well may be as much as two or three times that of a vertical well, the production factor can be enhanced as much as 15 or 20 times, making it very attractive.

Geology.com outlines a few other applications where horizontal drilling is being used:

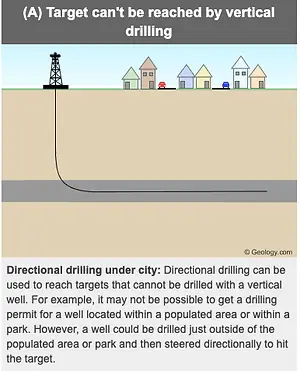

A) Hit targets that cannot be reached by vertical drilling.

Sometimes a reservoir is located under a city or a park

where drilling is impossible or forbidden.

This reservoir might still be tapped if the drilling pad is located on the edge of the city or park and the well is drilled at an angle that will intersect the reservoir.

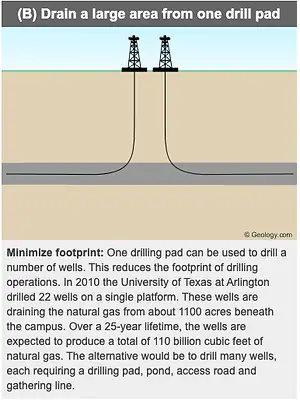

B) Drain a broad area from a single drilling pad.

This method has been used to reduce the surface footprint of a drilling operation. In 2010, the University of Texas at Arlington was featured in the news for drilling 22 wells on a single drill pad that will drain natural gas from 1100 acres beneath the campus.

Over a 25-year lifetime, the wells are expected to produce a total of 110 billion cubic feet of gas. This method significantly reduced the footprint of natural gas development within the campus area.

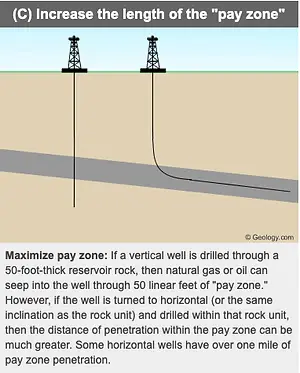

C) Increase the length of the “pay zone”.

Maximize pay zone:

If a vertical well is drilled through a

50-foot-thick reservoir rock, then natural gas or oil can seep

into the well through 50 linear feet of “pay zone.”

However, if the well is turned to horizontal (or the same inclination as the rock unit) and drilled within that rock unit, then the distance of penetration within the pay zone can be much greater. Some horizontal wells have over one mile of pay zone penetration.

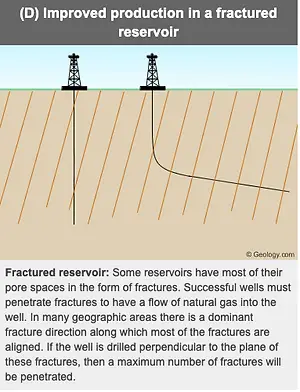

D) Improved production in a fractured reservoir.

Fractured reservoir:

Some reservoirs have most of their pore spaces in the form of fractures. Successful wells must penetrate fractures

to have a flow of natural gas into the well.

In many geographic areas there is a dominant fracture direction along which most of the fractures are aligned. If the well is drilled perpendicular to the plane of these fractures, then a maximum number of fractures will be penetrated.

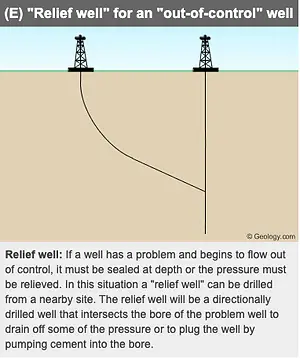

E) Seal or relieve pressure in an “out-of-control” well.

If a well is out of control, a “relief well” can be drilled to

intersect it.

The intersecting well can be used to seal the

original well or to relieve pressure in the out-of-control well.

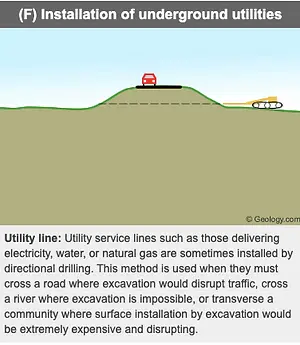

F) Install underground utilities where excavation is not possible.

Horizontal drilling has been used to install gas and

electric lines that must cross a river, cross a road, or travel under a city.

There you have it, folks!

I hope this helps give you a bit of insight if you are new or curious about the fracturing process. This technology is quickly becoming more efficient, safer for the environment, and effective.

By the way, you checked out our FAQ page yet? We have tons of information including definitions, common questions, and scenarios. Check it out!

If you have any questions or need help, please schedule a call with us or fill out the form below and we will be in touch shortly.

References:

https://geology.com/articles/horizontal-drilling/

Leave a Comment